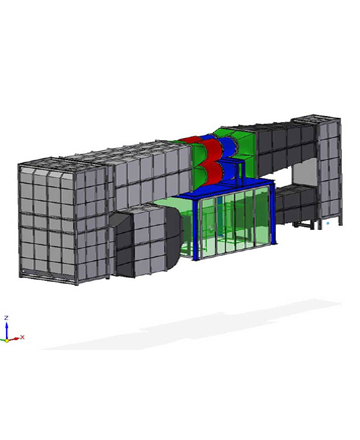

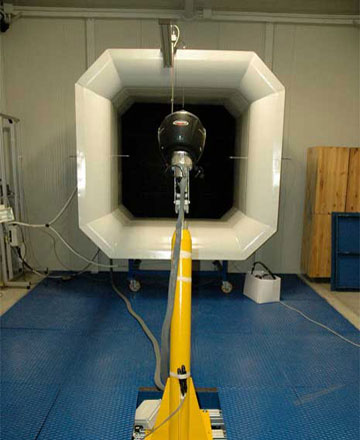

The Newton laboratory has an installation of a 280 kWatt subsonic wind tunnel. The air is designed to flow in a closed return wind tunnel, Goettingen type.

The test facility has been built to run with either an open or closed test section, as needed for particular experimental program. The required electric energy required is produced by mean of a power generator fully integrated with the wind tunnel.

Test section |

Maximum speed |

Contraction ratio (nozzle) |

Length to hydraulic diameter ratio |

1,25m x 1,25m - A=1,6mq |

240 kmh |

10,2 |

4 |

1,5m x 1,5m - A=2,3mq |

190 kmh |

7,1 |

3,3 |

1,9m x 1,9m - A=3,6mq |

125 kmh |

4,4 |

2,6 |

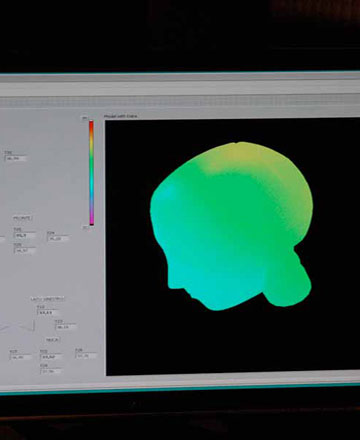

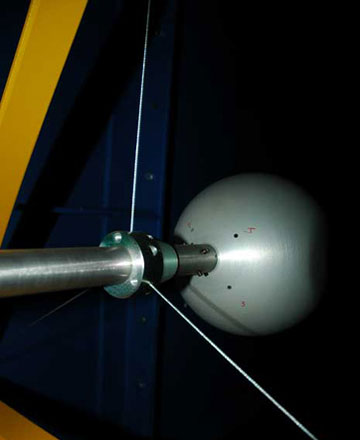

At present time the force and moments to calculate the aerodynamic forces are acquired by mean of n. 3 load cells and n. 3 torque meters.

For the actual tests regarding the aerodynamic characteristic of helmets this system has been embedded inside a standard headform.

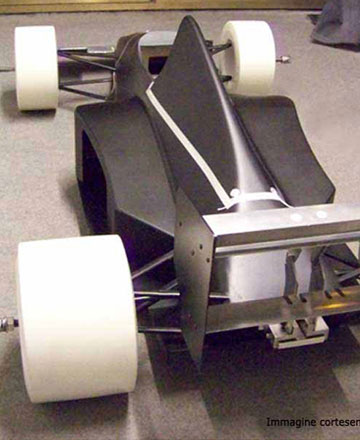

The model can be special prepared in order to accommodate small tubes (2mm diameter) to acquire the local pressures. At present time up to 18 pressure locations can be acquired.

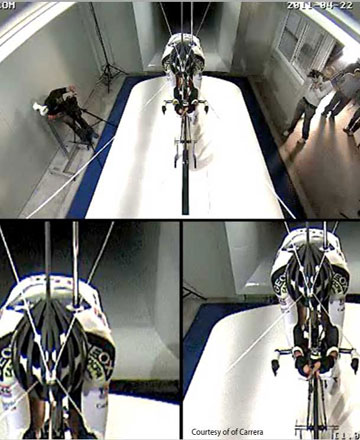

Information about the flow on the surface of the model being studied helps to investigate stagnation point locations, separation lines, location of boundary layer transition. In Newton lab we commonly use a smoke generator or, alternatively tufts. The tufts being light and flexible will align themselves with the local surface flow as a result of direct aerodynamic forces.